MSR Class Bushed Roller Steel Chains

MSR Class Bushed Roller Steel Chains

MSR Class Bushed Steel Roller Chain offers high strength and long wear, and is manufactured for heavy duty operation under severe conditions. This chain is made according to manufacturer's standards and may be interchanged with standard bushed roller chain of other manufacturers.

Style 1 have rollers that are taller than the sidebar.

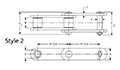

Style 2 has rollers that are equal to, or less than the height of the sidebar.

Style 3 has offset sidebars.

Style 4 is "deep link", or has sidebars that extend above the roller.

See the reference sketches to determine your style.

Dimensions are given in inches.

Style 1 have rollers that are taller than the sidebar.

Style 2 has rollers that are equal to, or less than the height of the sidebar.

Style 3 has offset sidebars.

Style 4 is "deep link", or has sidebars that extend above the roller.

See the reference sketches to determine your style.

Dimensions are given in inches.

Unit of Measure

| Items |

/Asset/MSR Style 2 Draw.jpg /Asset/MSR Style 2 Draw.jpg 378RX 1.654" Pitch Chain, Straight Sidebars |

/Asset/MSR Style 2 Draw.jpg /Asset/MSR Style 2 Draw.jpg 432 1.654" Pitch Chain, Straight Sidebars |

/Asset/MSR Style 2 Draw.jpg /Asset/MSR Style 2 Draw.jpg MSR2048 2.000" Pitch Chain, Straight Sidebars |

/Asset/MSR Style 2 Draw.jpg /Asset/MSR Style 2 Draw.jpg MSR2825 2.000" Pitch Chain, Straight Sidebars |

/Asset/MSR Style 2 Draw.jpg /Asset/MSR Style 2 Draw.jpg 81X 2.609" Pitch Chain, Straight Sidebars |

|||||

| Drawing | N/A | |||||||||

| Pitch | N/A 1.654 | N/A 1.654 | N/A 2.00 | N/A 2.00 | N/A 2.609 | |||||

| Diameter of Pin (E) | N/A 0.437 | N/A 0.437 | N/A 0.562 | N/A 0.558 | N/A 0.438 | |||||

| Overall Width - Cottered (C2) | N/A 2.16 | N/A 2.32 | N/A 2.82 | N/A 2.50 | N/A 2.08 | |||||

| Overall Width - Riveted (C1) | N/A 2.00 | N/A 2.16 | N/A 2.60 | N/A | N/A 2.00 | |||||

| Height of Sidebar (H) | N/A 1.13 | N/A 1.13 | N/A 1.50 | N/A 1.57 | N/A 1.12 | |||||

| Overall Chain Height (L1) | N/A | |||||||||

| Roller Diameter (D) | N/A 0.88 | N/A 0.88 | N/A 1.13 | N/A 1.00 | N/A 0.91 | |||||

| Head of Pin to Center Line (J) | N/A | N/A | N/A | N/A | N/A 1.00 | |||||

| Cottered End of Pin to Center Line (K) | N/A | N/A | N/A | N/A | N/A 1.08 | |||||

| Riveted End of Pin to Center Line (L) | N/A | N/A | N/A | N/A | N/A 1.00 | |||||

| Thickness of Sidebar (T) | N/A 0.19 | N/A .25 | N/A .25 | N/A .25 | N/A 0.16 | |||||

| Thickness of Inner Sidebar (T) | N/A | |||||||||

| Thickness of Outer Sidebar (T) | N/A | |||||||||

| Distance Between Sidebars (W) | N/A 1.00 | N/A 1.00 | N/A 1.00 | N/A 1.00 | N/A 1.07 | |||||

| Length of Bushing (X) | N/A 1.38 | N/A 1.50 | N/A 1.50 | N/A 1.50 | N/A 1.38 | |||||

| Avg. Ultimate Strength | N/A 20,000 lb | N/A 25,000 lb | N/A 59,000 lb | N/A 20,000 lb | N/A 24,000 lb | |||||

| Max. Recommended Working Load | N/A 2,100 lb | N/A 2,550 lb | N/A 3,450 lb | N/A 2,930 lb | N/A 2,100 lb | |||||

| Links per 10' | N/A 73 | N/A 73 | N/A 60 | N/A 60 | N/A 46 | |||||

| Avg. Weight | N/A 3.6 lb/ft | N/A 4.3 lb/ft | N/A 6.70 lb/ft | N/A 6.1 lb/ft | N/A 2.4 lb/ft | |||||

| Pins | N/A Carbon Steel, Heat Treated | N/A Carbon Steel, Heat Treated | N/A Alloy Steel, Heat Treated | N/A Alloy Steel, Heat Treated | N/A Carbon Steel, Case Hardened | |||||

| Bushings | N/A Alloy Steel, Case Hardened | N/A Alloy Steel, Case Hardened | N/A Carbon Steel, Case Hardened | N/A Carbon Steel, Case Hardened | N/A Carbon Steel, Case Hardened | |||||

| Rollers | N/A Alloy Steel, Heat Treated | N/A Alloy Steel, Heat Treated | N/A Alloy Steel, Heat Treated | N/A Alloy Steel, Heat Treated | N/A Carbon Steel, Case Hardened | |||||

| Sidebars | N/A Carbon Steel, Heat Treated | |||||||||

| Style | N/A 2 | |||||||||

| Attachment Available | N/A | N/A | N/A D5 | N/A | N/A H | |||||

| Note | N/A | |||||||||

| Applications Served | N/A | N/A | N/A | N/A | N/A car wash citrus processing clean grain and return elevators fertilizer conveying food processing forest products grain handling manure spreaders produce washdown | |||||

|

|

||||||||||